-

Hydraulic Series

The structure of the hydraulic leveler incorporates box construction deck assembly with heavy duty lug hinge design. Hydraulic levelers have added safety features and save valuable time in operation and maintenance. Dimensions include 6’, 6’6”, & 7’ standard widths and 6’ & 8’standard lengths. Other lengths may be available upon request. Standard capacities for the LHP Series are 25K, 35K, 40K, CIR (Comparative Industry Rating).

• Simple push button control

• Four sided box construction

• Heavy duty lug hinge design

• Full hydraulic lip activation

• Velocity safety stop

• Lockout/tagout maintenance strut

• Night locks/cross traffic support

• Motor overload protection

• Low maintenance design

• Full range toe guards

• Two (2) DB-13 molded rubber bumpers

Hydraulic Cylinder

Pump And Motor

Push Button Controls

-

Air Powered Series

The air powered leveler provides dependability and superior structure This leveler is available in a wide range of sizes and capacities and can be modified for special applications. Standard AP Series sizes include 6’, 6’6”, & 7’ standard widths, and 6’, 8’ & 10’ standard lengths. Standard capacities for the AP Series are 20K, 25K, 30K, 35K, 40K, 45K, & 50K CIR (Comparative Industry Rating).

• Simple push button control

• Four sided box construction – deck assembly

• 115V single phase motor with simple plug end

• Unique yieldable full lip extension mechanism

• Below dock end loading capability

• Lockout/tagout maintenance strut

• Lip supporting service strut

• Night locks/cross traffic support

• Multiple position safety stop

• Full range toe guards

• B410-14 laminated bumpers

Motor

Control Box

-

CentraAir Series Air Powered

The CentraAir™ (CA) Series dock levelers incorporate the use of common plant air combined with an industrial automotive grade air bellows system to raise and lower the platform. The CA Series can be push button or manually activated via a lanyard control located at the back of the leveler. This leveler is available in a wide range of sizes and capacities and can be modified for special applications. Standard CA Series sizes include 6’, 6’6”, & 7’ standard widths, and 6’, 8’ & 10’ standard lengths. Standard capacities for the AP Series are 25K, 30K, 35K, 40K, 45K, & 50K CIR (Comparative Industry Rating).

• Push Button or Lanyard Control

• Ideally Suited for Power Starved Applications

• Powered by In-Plant Air System or Dedicated Compressor

• Proven Industrial Air Bellows Technology

• CleanSweep™ Frame

• Low Maintenance Design - Few Moving Parts

• Automatic Lip Extension

• Below Dock End-Loading

• Lockout/Tagout Maintenance Strut

• Multiple Position Safety Stop

• Night Locks/Cross Traffic Support

Lanyard

Bellows

-

Mechanical Series

The Mechanical Series incorporates the manufacturing efficiency of the “Lug Hinge” deck design with standard box construction to produce a reliable, economic mechanical dock leveler. Mechanical Series levelers come in 6’, 6’6”, & 7’ standard widths and 6’, & 8’standard lengths. Other lengths may be available upon request. Standard capacities for the Mechanical Series are 20K, 25K, 35K, & 40K CIR (Comparative Industry Rating).

• Four sided box construction - deck assembly

• Multi-position structural steel safety legs

• Extended range float/hold-down mechanism

• Yieldable lip plate

• CamControl™ counter balance assembly

• Lip Drive™ positive lip extension

• Lockout/tagout Maintenance Strut

• Night locks/cross traffic support

• Working range toe guards

• Two (2) DB-13 molded rubber bumpers

Lift Arm Assembly

Hold Down

-

Vertical Storing Series

Vertical Storing Series hydraulic dock leveler offers unmatched environmental control for customers with food storage or temperature sensitive applications. By storing in the vertical position, the Vertical Storing Series allows the overhead door to form a perfect seal to the pit floor. Vertical Storing Series levelers offer improved cleanliness, overhead door protection, increased security, improved productivity, and easy maintenance. These levelers come in 6’, 6’6”, & 7’ standard widths, and 5’ & 6’ standard lengths. Other lengths may be available upon request. Standard capacities for the Vertical Storing Series are 40K, 45K, & 50K CIR (Comparative Industry Rating).

• Full featured push button control box

• Structural steel support members

• Power-up and power-down control

• Free float working range

• Mechanical storage locking mechanism provides redundant safety

• Push button release of storage prop

• Dual maintenance prop

• 3” high run-off guards

• 10” above, 8” below dock service range

• Overhead door interlocks (dry terminal)

• Rear embed channel with factory installed hinges

• Two (2) VB420-11 laminated dock bumpers

Prop Kicker

Control Box

-

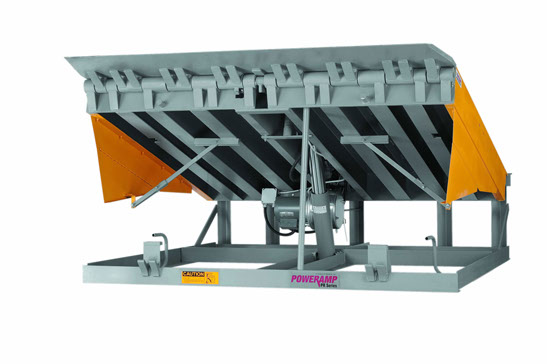

EOD Series

Edge-of-dock levelers mount directly to the dock face and provide a recommended working range of +/-3" and a maximum operating range of +/-5" above or below dock. The units are offered with either mechanical or hydraulic operation. Mechanically-operated edge-of-dock levelers are the largest selling edge-of-dock levelers in the industry. Our dual extension spring lift mechanism offers proven efficiency and durability. Careful engineering and rugged construction ensure extended life. Operation is safe and easy. Hydraulically-operated edge-of-dock models offer the convenience and safety of push-button control. Poweramp’s hydraulic design, featuring power extension and retraction of the lip and deck and hydraulic lip lock, is the finest in the industry. Our exclusive speed control adjusts leveler descent speed.

• 15” lip standard

• Rust-inhibiting primer coat

• Low-profile design

• 15” bumpers on mechanical units and 18” on hydraulic units

• Grease fittings

Hydraulic Fully Raised

Manual Fully Raised